What Machines are used for ADA signs?

ADA stands for Americans with Disabilities Act, established in 1990. This law was created to give equity to those who are disabled, and they fall into two branches: physical and mental. For more information on the history of ADA, check out our past blog that covers it, here.

We have already covered some of the basics such as what ADA signs are and the difference between tactile and braille signage, but we have yet to discuss the different types of machinery used to make these wholesale signs! Before you can even begin to start designing your signs, you need to make sure you have the correct equipment.

Why is ADA Sign Machinery so Important?

It is very important to have the right machinery because of the list of requirements that must be met when manufacturing tactile signs. Some of these guidelines include braille lettering and readability. We will be breaking down some of the requirements:

- Braille: Braille lettering includes a number of requirements for ADA signs including the dot height and diameter. You must have a machine that can do this precisely, or it will be difficult for those who are blind to understand what the braille is supposed to say.

- Readability: Not everyone is completely blind, nor can everyone read braille. It is important that you adhere to the guidelines on easy readability. This includes being able to print easy to read fonts and having the right amount of space between each grouping of words. The lettering also can vary depending on whether you choose to do tactile text or just plain printed text.

Recommended Reading: Understanding Types of ADA Signs

What ADA Manufacturing Tools are Needed?

Because of how complex ADA signage is, you will need a wide range of tools and machinery to ensure that you are manufacturing them properly. We will be highlighting 4 main ones below, but there are many other machines out there that you may need depending on what kind of signage you are manufacturing.

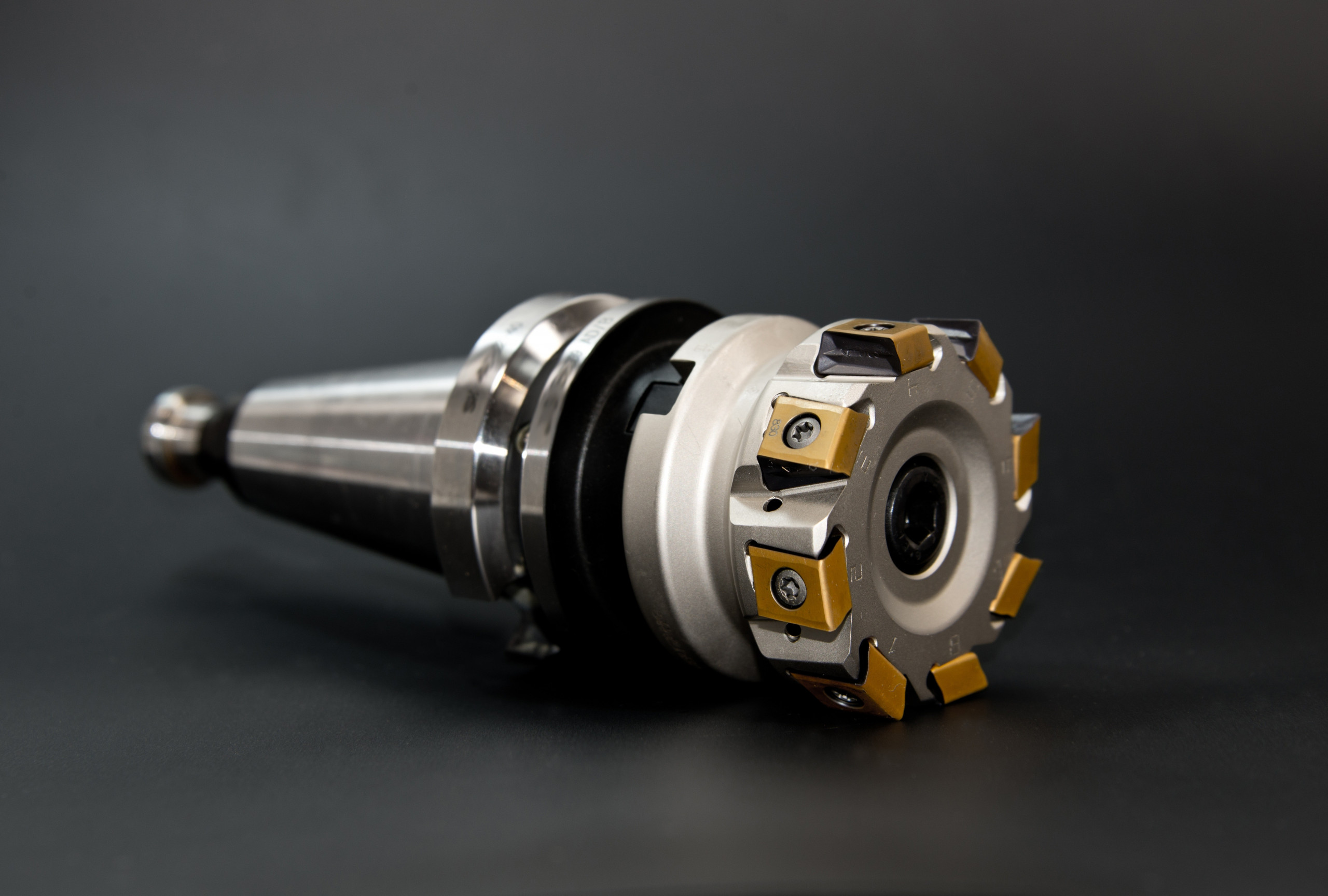

- Router: CNC routers are very common machines and a MUST when you are manufacturing ADA signage. According to Vision Engraving and Routing Systems, “[Our] CNC routers are known for American made rugged reliability. Ideal for serious production shops, our CNC machines do precise, repeatable work, so you can capitalize on single or large run jobs & projects.”

- UV Inkjet Printer: Commonly used for direct-to-substrate printing. If you already own a sign shop, chances are you might already have one. Rather than printing on vinyl and then placing that material on the signage, using a UV inkjet printer allows fabricators to print directly on the substrate. This results in a longer-lasting finish, with text and graphics that won’t peel over time.

- Engraver: When selecting an engraving machine for ADA signage, there are 2 factors to consider: the speed and strength of the motor and the engraving area. The speed and strength determine not only the types of material you can engrave on but also how long you can safely operate the engraving machine without causing any damage. The engraving area sets the limitations for how large of an item you can engrave on. You would also need to buy a raster pen kit for this as well.

0 Comments